Rebar can be a basic metal bar or block and that is frequently utilized in reinforced concrete and reinforced masonry buildings. These rebars are commonly designed from carbon metal and can be recounted as reinforcing metal or perhaps reinforcement. Under Structural BIM Expert services Rebar detailing is known as a willpower of creating fabrication or shop drawings of steel reinforcement for that development method. The location fabrication drawings that are generated according to design and style drawings for reinforcing steel are Rebar Detailed drawings. Engineers and Architects make structure drawings to bring about the needed strengths based upon the rebar detailing giving you with diameter, bar shapes, quantities, duration of bars to facilitate the Online page for keeping away from delays and wastage thus rushing The complete building course of action.

Each individual rebar is thorough representing a shape, length, and diameter depending on the requirements in the layout drawing. The Rebar placement will then be shown in higher detail which implies the concrete deal with, actual spot, and Particular way of placement as essential. The rebar aspects and bar bending schedules will clearly show bar diameter, bar notation, the quantity of bars, fat with the bars, and size of each bar along with mentioning the general excess weight for that overall listing of bars positioned inside the drawing. Over the preparation of rebar details, the inventory lengths of bars are held in perspective to guarantee there is totally no wastage from the substance.

Rebar Detailing and Reinforcement concrete detailing is usually modeled and coded in 3-dimension utilizing the 3D Modelling technology like BIM Modelling Companies. The specialized rebar detailing application like Rebar CAD and AutoCAD utilized for this goal can assist every single member with the structural engineering to prepare types, doc, track, and retain Over-all Manage.

Owning understood The fundamental notion of rebar detailing a place of structural BIM modeling, let's attempt to check out the need for it in the general development approach is. Some in the good reasons are:

Value of Rebar detailing in Structural BIM Modeling

Though 2nd drawings and bending schedules are frequently produced and presented, the 3D design is often issued to any or all the c's users beginning from the consulting engineer and contractor departments into the metal fixers which might be from the walk-out on-website. The mix of such two become especially ideal for internet site staff where by web-site limitations or congestion of reinforcements continue being unidentified until finally there are actually reinforcement and fixation on area. For each and every bar, the precise posture of fixing is revealed within the 3D model together with any hindrances or obstructions.

Developing detailing reinforcements in 3D to the 2nd method is not simply more quickly but modeling rebar during the 3-dimensional ecosystem will help eliminate clashes. Though modeling It truly is feasible to visualize if any in the bars Never take care of having a decided space, therefore determine these kinds of clashes during the rebar drawings. There is Probably the facility to assessment the reinforcement in entire detail like a specific element representation prior to it getting being ordered from the fabricator and reinforcing steel suppliers Wollongong complicated cages are assembled off-site.

When you can find the appropriate rebar detailing Answer accessible, a robust and exact reinforcement product could be obtained by importing structural calculations through the structural Assessment plan. With Automation associated the alterations are simply reflected inside of 3D rebar detailing along with needed updates to drawings and schedules swiftly when adjustments are manufactured in other places contrary to obtaining to conduct guide alterations to second sections and views.

As opposed to based on handbook enter from paper schedules, the rebar fabricator can extract knowledge straight from the model for the equipment. The concrete pours could be nicely-defined inside the product with other facts like quantities and volumes to make certain a lot more accuracy in managing product deliveries. This will permit bigger control and bring about less wastage and minimize in In general prices.

Obtaining 3D thorough electronic versions will not be planning to prohibit the ability to the solitary-period like that from the engineering and detailing phase but could be employed inside the phases. Owning reinforcement thoroughly modeled in 3D, the contractor is certain that it will fit in locations if the time will come so that it's fastened on-website. The information during the design is usually utilised during the field to permit contractors to perform a design-dependent format by making use of robotic complete station gadgets in addition to monitoring rebar and materials and pinpointing spot are likely to necessary.

Fixers existing on-web-site looks within the model natural environment to your rebar detailing to accurately fully grasp its software, i.e. precisely what is necessary spot as an alternative to according to their interpretation of conventional 2nd drawings.

The structural engineers can commonly plus much more swiftly make layout studies, schedules, and drawings out of your 3D product in comparison with 2D layouts, therefore enhancing style and design effectiveness. There is extra accuracy in selling price projection In line with the rebar quantities created from the 3D product because These are additional dependable than the 2nd drawing acquire-offs. Not merely this the portions are totally traceable, permitting comparisons and checks to obtain executed simply.

Using these causes, we can easily conclude that Rebar Detailing a self-discipline of Structural BIM Modelling Expert services is one inside the critical conditions with the In general results from your challenge everyday living cycle. To summarize, owning Rebar Detailing the rebar contractor can give attention to creating rebars there will probably be no ought to estimate reinforcement needs for procurements at the web site as a result of successful 3D models. The model will depict the requirement of anchors and laps inside the drawings thus making sure design and style adequacy together with lowering wastage. The overall waste and time delays are lowered at the website since Just about every on the shape drawings could be readily available. Based upon these records the bars is often conveniently fabricated dependant on the designs and number of bars expected.

Rider Strong Then & Now!

Rider Strong Then & Now! Kirk Cameron Then & Now!

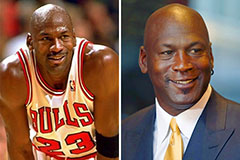

Kirk Cameron Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!